Pre-Treatment

To achieve certain surface effects or colour intensities, it is necessary to pre-treat raw wood with stains or primers. Among these are, for example, surfaces with a raw wood look, greyed and aged surfaces, and two-tone effects. Also with pre-treatment, the microporous properties of Polyx® surfaces are still guaranteed.

Sapwood Stain

> Waterborne – physical curing

> Stains sapwood to match it to the rest of the wood

> For example, on Oak and Walnut

> Requires further treatment

> Solvent-free

> Only partial coating possible

Pigment Stain

> Waterborne – physical curing

> Intense colours; two-tone effects

> Transparent

> Requires further treatment

> Solvent-free

> Approx. 20-40 g/m²

Reacitve Stain

> Waterborne – physical curing

> Grey or antique effects

> Transparent

> Requires further treatment

> Solvent-free

> Approx. 20-40 g/m²

Primer

> Waterborne – physical curing

> For a raw wood look

> Transparent

> Requires further treatment

> Solvent-free

> Approx. 20-80 g/m²

Treatment

For the treatment of the surface, various systems are available. They are distinguished by curing process, application method or area of use. The treatment implements the requirements that were previously determined for the surface.

Oxi-Polyx®-Oil

> Industrial hardwax-oil for oxidative curing

> Surface with a natural look and feel

> Transparent or clear, various sheens

> Pre-treated or factory-finished surfaces

> 1 or 2 coats in the same system or a system consisting of primer and Top Coat

> No hidden solvents (SVOCs)

> Approx. 15-40 g/m²

UV-Polyx®-Oil

> Industrial hardwax-oil, curing with UV lamps

> High resistance with low application amounts

> Transparent or clear, various sheens

> Factory-finished surfaces

> One system consisting of primer and Top Coat

> 100% curing, no solvents

> Approx. 15-20 g/m²

Hybrid-Polyx®-Oil

> Industrial hardwax-oil, curing with UV lamps

> Extremely matt natural surfaces

> Clear, various sheens

> Factory-finished surfaces

> Top Coat with Oxi-Polyx®-Oil or UV-Polyx®-Oil

> No hidden solvents (SVOCs)

> Approx. 15-20 g/m²

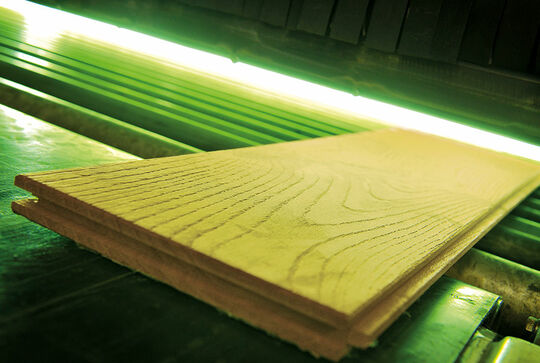

LED-Polyx®-Oil

> Industrial hardwax-oil, curing with UV-LED lamps

> No heat development, no exhaust system needed

> Transparent or clear, various sheens

> Factory-finished surfaces

> One system consisting of primer and Top Coat

> 100% curing, no solvents

> Approx. 15-20 g/m²

Spray-Polyx®-Oil

> Industrial hardwax-oil for oxidative curing

> For manual or machine appliations

> Opaque, transparent or clear, various sheens

> Pre-treated or factory-finished surfaces

> 1 or 2 coats in the same system or a system consisting of primer and Top Coat

> No hidden solvents (SVOCs)

> Approx. 40-80 g/m²

Panel Wax

> Water-wax emulsion - phyical curing

> Water repellent, wear-resistant & smoothen the surface

> Opaque, transparent or clear, also with UV blockers

> Factory-finished surfaces

> One system consisting of primer and Top Coat

> No hidden solvents (SVOCs)

> Approx. 80-180 g/m²

Care

Use the power of a strong brand to your advantage and recommend original Osmo care products. These are available in over 70 countries worldwide. Therefore, no matter where your customers are, they are always in good hands.

Wash and Care

> For the regular cleaning and care of all surfaces treated with Polyx® Systems

Liquid Wax Cleaner

> For refreshing dull surfaces treated with Polyx® Systems

Maintenance Oil

> For preservation the original properties of a Polyx® surface over many years